PROJECT LIFECYCLE MANAGEMENT - PROCUREMENT

We help clients who intend to create a new infrastructure project, we provide services for complete equipment and materials procurement on infrastructure projects.

Global purchasing capability Delivery Schedule Management Quality control awareness Excellent Transport Planning

PROCUREMENT

The CMC procurement department has a vital role and responsibility to play because it is in the middle position of the EPC. The EPC stands for Engineering, Procurement, and Construction. These three are the main components of plant engineering. The procurement department connects engineering and construction by cooperating closely on projects and the supply chain.

Tasks of the Procurement Department

The main task of the CMC Procurement department includes but is not limited to the following activities:

- Procurement of materials within the working budget of projects

- Production progress control after order, and

- Quality control by inspections and transportations to the sites in line with the project schedule.

Our people at the procurement department are highly skilled and are sensitive to the market trends, possess a good understanding of the international regulations, have good judgment for prices, strong in negotiating with suppliers, and

Key attributes of our procurement department are the sensitivity to market trends, good or correct understanding of international regulations, excellent judgment for prices, strength to negotiate with suppliers, and a strong drive for tough quality requirements for our projects.

To guarantee that our construction schedules are maintained, we focus on ensuring that our purchased equipment and materials are delivered to our construction site according to the planned delivery schedule.

AT CMC, YOU ARE A FAMILY.

CMC’s Core Values are an integral part of our business. Internally and externally, we consistently align ourselves with the foundational values that our founders had built upon.

Quality. Integrity. Collaboration. Innovation. Leadership.

Global purchasing capability

Procurement of plant engineering is on a much larger scale than in usual industries in terms of the size of materials, price, and the number of people working on a project. This exercise takes thousand of purchase orders if not a hundred when you are dealing with big projects sourcing out to makers in several countries.

The CMC procurement department is highly regarded to be sensitive to suppliers from all over the world when it comes to negotiating a reasonable price on equipment and materials for a project. From our experience, some procurement operations range between six months to two years, others last over two years including inquiry, negotiation, order, production control, and quality control.

Delivery Schedule Management

Timely delivery of the equipment and material is the most important factor for timely construction completion of the plant. To keep the construction schedule on track, CMC takes the necessary actions while comprehensively judging the means of securing the delivery date. Our procurement department pays close attention to suppliers’ overall manufacturing process and continuously exchanges information with other internal departments. Good communication skills and collaborations with all stakeholders are key to a successful procurement process.

We monitor and are sensitive to carefully looking for any sign of delay when it comes to purchasing and delivery of equipment and materials for the project. We proactively address any indication of delivery delay and takes every possible measure to prevent the delivery delay.

Quality Control Focused

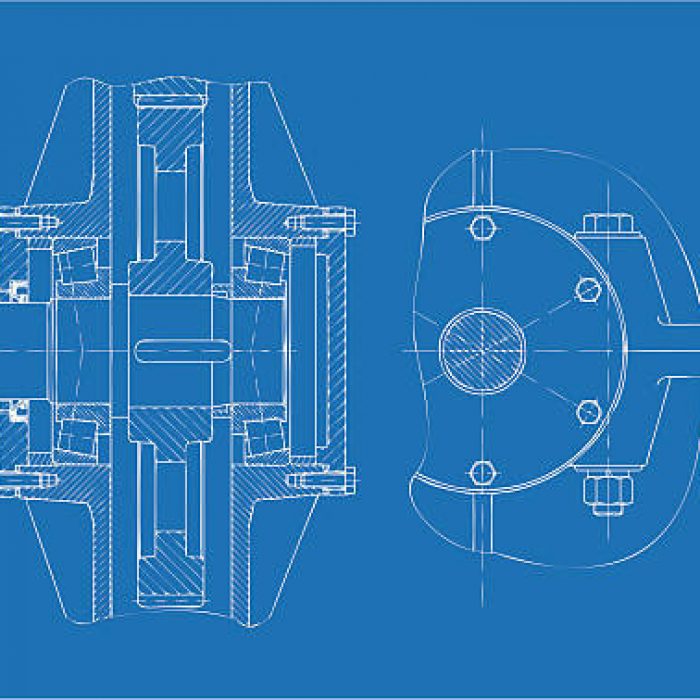

In our procurement work, we translate engineering requirements, which are drawn on blueprints, into tangible items that are needed for the construction of our infrastructure projects.

Our procurement is a key role of EPC and the most important part of our task is quality control. Ordered materials will be inspected through every stage of the manufacturing process until they meet the requested quality level. Quality control starts with CMC, our suppliers, and other organizations, including the clients based on a precise, efficient and effective inspection plan.

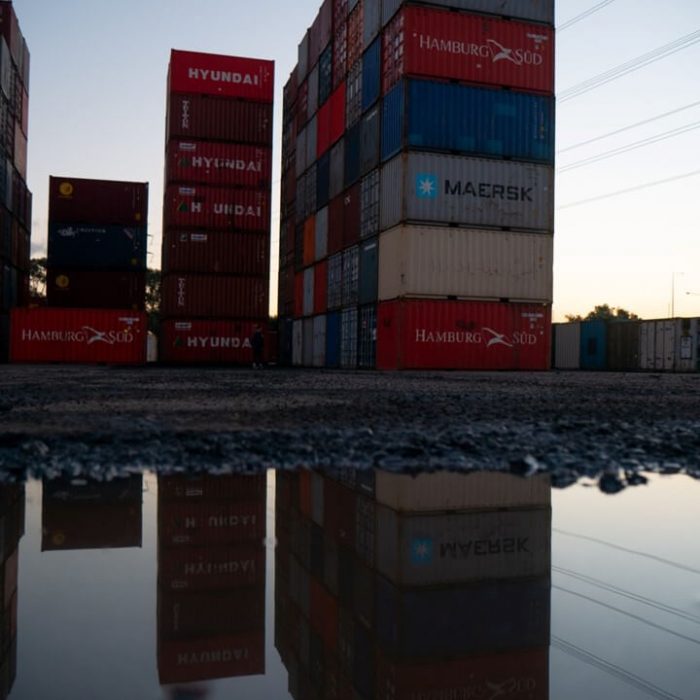

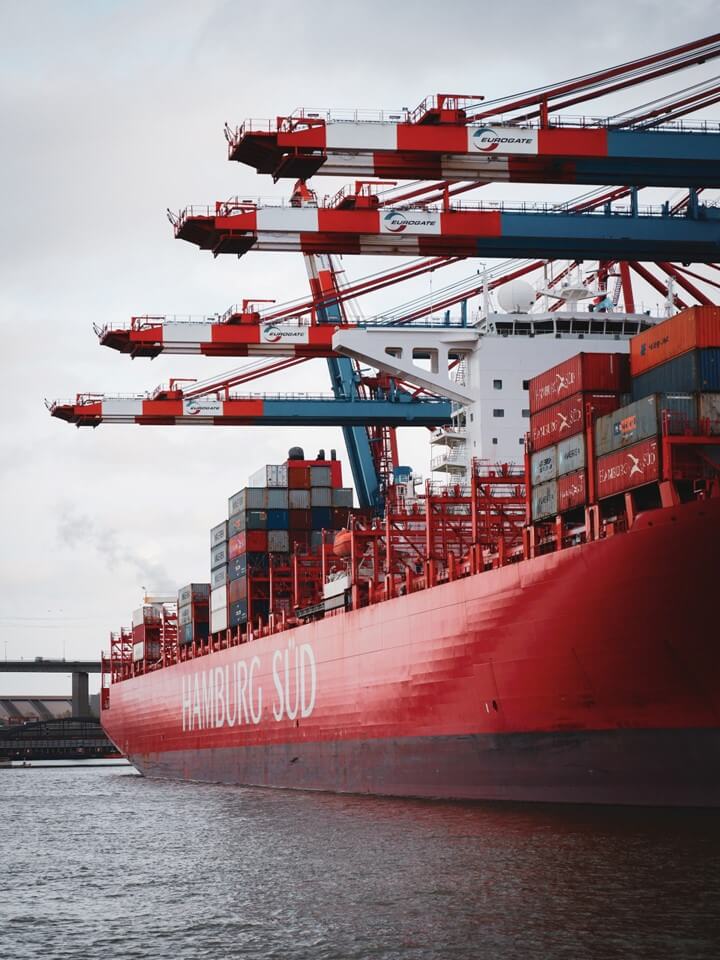

transport planning Management

Materials and equipment are usually transported to sites by ship from supplier’s shops, and the logistic process is reviewed on time. The process is influenced by the changing schedule of material production or weather condition over the ocean. Being organized throughout its schedule, mode, or route of transport is very important. The materials are sometimes extremely heavy and/or large, and the schedule takes into consideration transport conditions such as roads and bridges, the route to the site, and special custom clearance in the site countries.

Contact Us

Give us a call or send us a message to find out more about our Company, our culture, our solutions, or our services. Choose what suits you the best.

We work better when we all work together!

Join Our Team Your talent will shape our history

Our road to success lies in recruiting, attracting, and retaining the best people and developing them into professionals to excel in their respective fields.

We offer careers in different areas of specialties. If you believe you have what it takes to help us become successful, we would like to hear from you.

Join our team today, and together we will grow!